GM-GX Triple-Action Protective Coating: Insulates, Waterproofs, and Prevents Mold with Rigid Aerogel

- Model

- GM-GX-2

Item specifics

- Aerogel Coating

- Hydrophobic type

- Density

- 450 g/L

- Sanding Property

- Can be sanded manually

- Coverage

- 0.48 m²/L (2mm thickness)

- Dilution

- Up to 5% water addition based on coating condition

- Recommended Coating Thickness

- Above 2mm, apply at least 2 coats

- Curing Time

- 8-24 hours

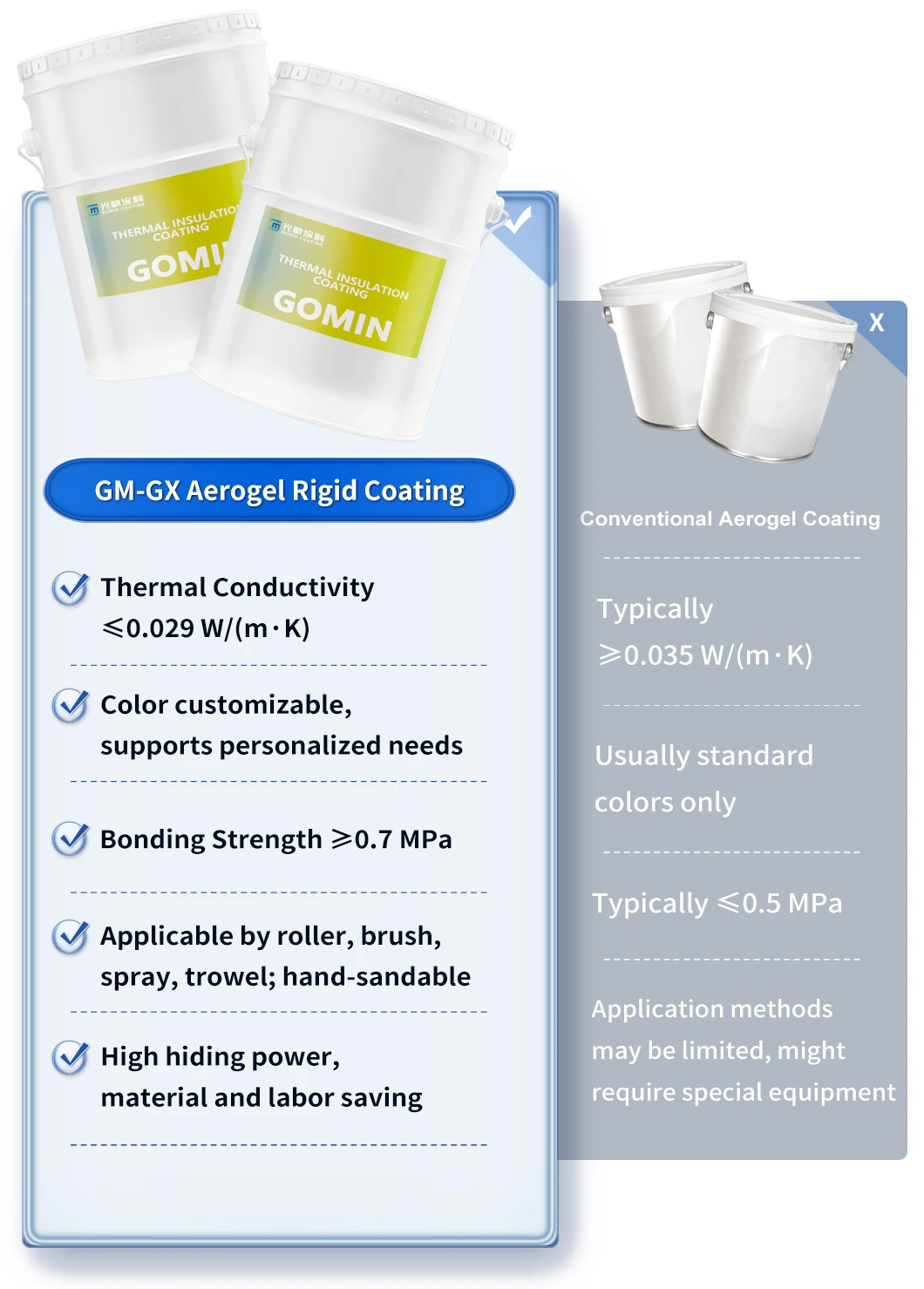

- Application Methods

- Rolling, brushing, spraying, troweling

- Operating Temperature

- -45°C to 200°C

- Packaging Specifications

- 20L,125L

Review

Description

Applied to building interior and exterior walls, roofs, and factory buildings, etc.

Test Item | Unit | Test Requirement | Test Result | Judgment |

|---|---|---|---|---|

Thermal Conductivity | W/(m·K) | ≤0.065 | 0.029 | Pass |

Thermal Resistance | (m²·K)/W | ≥0.3 | 0.45 | Pass |

Condition in Container | / | No hard lumps after stirring, uniform state | No hard lumps after stirring, uniform state | Pass |

Alkali Resistance (48h) | / | No abnormalities | No abnormalities | Pass |

Water Resistance (48h) | / | No abnormalities | No abnormalities | Pass |

Low-Temperature Storage Stability | / | No deterioration after three cycles | No deterioration after three cycles | Pass |

Water Absorption | g/10min | ≤2.0 | 1.9 | Pass |

Film Flexibility (50mm diameter) | / | No cracks | No cracks | Pass |

Bond Strength (under standard conditions) | MPa | ≥0.6 | 0.7 | Pass |

Initial Drying Crack Resistance (6h) | / | For products with single-layer application thickness ≤1.5mm, 1mm without cracks | 1mm without cracks | Pass |

VOC Content | g/L | ≤100 | 0.5 | Pass |

Formaldehyde Content | mg/kg | ≤50 | Not detected | Pass |

Total Content of Aromatic Hydrocarbons [benzene, toluene, xylene (including ethylbenzene)] | mg/kg | ≤100 | Not detected | Pass |

Total Content of Alkylphenol Ethoxylates | mg/kg | ≤1000 | Not detected | Pass |

Heavy Metal Content (%) | GB/T 26125-2011 (Detection limit: 0.001%) | Lead (Pb) | Not detected | Pass |

|

| Cadmium (Cd) | Not detected | Pass |

|

| Mercury (Hg) | Not detected | Pass |

|

| Hexavalent Chromium (Cr VI) | Not detected | Pass |

(1) This product is intended to be applied only by professional construction personnel in industrial fields in accordance with the product manual, material safety data sheet, and recommendations provided on the packaging container.

(2) The construction site should be kept away from sparks, open flames, and other ignition sources. Smoking is strictly prohibited.

(3) When performing spraying operations, protective masks, gloves, and other protective equipment must be worn to avoid skin contact or inhalation of dust.

(4) Before use, the coating must be thoroughly stirred to avoid sedimentation or layering. If the coating is too thick after stirring, an appropriate amount of clean water can be added for dilution, but the amount of water added should not exceed 5% of the total coating volume.

(5) Application can be carried out using rollers, brushes, or spraying equipment. During application, ensure even coverage without missed spots. It is recommended to apply in two coats, allowing the first coat to dry before applying the second, to ensure coating thickness and uniformity.

(6) The construction site should be well-ventilated to avoid prolonged exposure to high concentrations of coating materials.

Q: Can you provide samples?

A: Yes, samples are free of charge. However, shipping costs or freight expenses need to be covered by you.

Q: Can you produce products according to customer requirements?

A: Yes, custom orders based on provided samples are welcome. We are a professional manufacturer of coatings, including high-temperature coatings, thermal insulation coatings, and more.

Q: What are the payment terms?

A: We prefer T/T with 30% deposit, and the balance to be paid within 7 days after the Packing List copy is sent.

Q: Can we use our freight forwarder?

A: Yes. We have our cooperating freight forwarders, but if you prefer, you may use your own freight forwarder when feasible.